Who We Are

PRS Geo–Technologies® is a global geotechnical engineering company that helps pave a greener future. For more than 25 years, PRS combines advanced cellular confinement technology with proven engineering expertise to implement solutions for load support, slope and channel protection, earth retention and landfill and reservoir applications worldwide.

The very heart of our technology is a rigid and durable cellular confinement system for soil stabilization, Neoloy® Tough-Cells. With PRS Neoloy Tough-Cell solutions you can build better pavements, over any soil, while saving costs and time required for your project.

We believe advanced technologies should be green — this is why our solution is based on utilizing marginal land, soils and recycled materials. Neoloy needs less asphalt and less aggregate while utilizing locally available soil for structural infill. This makes our advanced cellular confinement technology highly sustainable.

In thousands of successful projects, implemented in 80 countries worldwide and validated by more than 100 published papers – PRS has proved that in the 21st century we can leverage advanced technology to build a more sustainable future. Pave better roads with less resources and time.

PRS is Leading the Tough-Cells Revolution. Join It. Lead It.

Our Story – New Generation of Cellular Confinement Systems

History… Although ancient cultures used soil improvement techniques, for example using branches to create access roads over swamps, the basic geocells were developed in the late 1970’s by the United States Army Corps of Engineers to land heavy military equipment on sandy beaches. The first geocells were made of cardboard, cloth, aluminum and eventually polymer plastic.

Commercial use… In the 1980’s geocells made from High Density Polyethylene (HDPE) were applied to commercial applications. Over time leading engineers and engineering companies realized these HDPE “soft-cells” were lacking engineering properties and design methodologies required for long term use in load support or other permanent use applications.

The new generation… With the emergence of advanced polymer technologies, PRS embarked an extensive R&D program with world renowned geotechnical experts and institutions to develop a Novel Polymer Alloy (NPA), which was used to manufacture Neoloy® ‘Tough-Cells’. Neoloy Tough-Cells provide superior engineering properties – high elastic stiffness, low deformation (creep) and high tensile strength, making them suitable for load support, heavy-duty and long-term use.

Proven in the lab and the field… For the past 20 years the engineering performance of Neoloy Tough-Cells established and proven in more than 100 professional published papers and in thousands of projects worldwide. The collaborative testing included leading institutes and authorities around the world, such as the US Federal Highway Administration (FHA) and state Departments of Transportation (DOTs), the Federal Railroad Administration (FRA), KOAC-NPC Road Standards Institute, and other geosynthetics standards and transportation agencies worldwide.

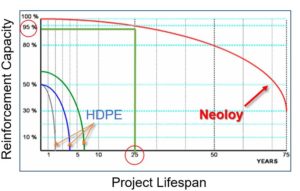

Neoloy Tough-Cells provide 95% performance after 25 years

How to Choose the Right Geocell for Your Project

PRS Solution – What our Customers Say About Us

For the last 15 years PRS Neoloy Geocells solution has proven results worldwide. The following are sample recent projects and testimonials.

New Airport International of Mexico built on a Swamp: leading international engineering consultants and the NAICM authority selected PRS-Neoloy-330 Category C Tough-Cells after extensive testing and trials on problematic soils (CBR <1%).

Mario Gonzales, Ancora Pavement Engineering, Mexico

Fast Military Access Road Construction, UK Ministry of Defence (MOD): PRS was chosen due to its high-modulus Neoloy Tough-Cells, quality management, large production capability and proven experience in Route TRIDENT Afghanistan, where it helped save lives, reduced the amount of materials used by 75% and save on construction time while under fire.

Lieut. Colonel M T G Bazeley Royal Engineers

PRS Engineering – Optimizing Costs and Performance

The PRS Engineering Division provides professional geotechnical design for a wide range of civil engineering projects. Based on the vast R&D and thousands of projects implementations, the unique improvement factors of PRS-Neoloy Tough-Cells are embedded in proven design methodologies. In addition, to fully optimize costs and performance, PRS has 4 different Neoloy categories based on required strengths to optimize design and costs.

PRS Engineering services:

- Expert geotechnical solutions for unpaved roads, airstrips, paved roads, shipyards, railways, heavy-duty haul roads, walls, slopes and channels

- Proven design methodologies based on PRS-Neoloy Tough-Cells

- 100+ published articles on R&D and field trials with PRS-Neoloy Tough-Cells

- Conduct pavement optimization for value engineering

- Academy and Design Seminars for engineers

Learn More About PRS Geotechnical Engineering

PRS – the Largest Supplier of Tough-Cells Worldwide

PRS engineering design optimizes the geocell properties according to the specific project requirements and pavement configurations. PRS manufactures both HDPE (soft-cells) and Neoloy (Tough-Cells) according to their application. PRS has its own geocell factory to ensure high-capacity production at the highest quality standards. PRS can produce over 200 containers per month in this facility making it the largest geocell manufacturer in the world.

PRS attests to its manufacturing competence, integrity, dependability, responsiveness to ensure the scheduled delivery and quality of the product. The PRS factory utilizes the some of the world’s most advanced plastic extrusion technologies, as well as the state-of-the-art QA and testing procedures.

Learn more about PRS Quality Assurance