The Stepped Isothermal Method (SIM) test is used to predict the creep (elongation) of polymers for the project design life (ASTM D6992). SIM measures the cumulative plastic distortion of the polymer product by subjecting it to a constant load at different temperatures for a specified time. The SIM method enables calculation of the allowed strength for long-term design.

The video above demonstrates a SIM test of Neoloy Tough-Cells vs. HDPE Soft-Cells. The weights represent a heavy-duty load (6.1 kN/m). The temperature is raised in 4 steps to simulate acceleration of time to a design life of 75 years.

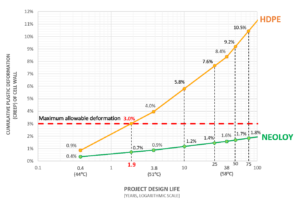

The end of service life in the SIM test is not based on a geocell wall or seam rupture, but rather on a permanent plastic deformation exceeding 3%. Plastic deformation above 3% causes expansion in the cell walls such that the cell loses its compaction; leading to a loss of confinement and potential failure.

Download Neoloy® Tough-Cells Specifications to compare Neoloy Tough-Cell SIM Tests Results

Conclusion: Neoloy Tough-Cells – The only qualified geocells for long-term

The test results summarized in the graph below show the relationship between (tension) creep and project design life and infill settlement. The graphs benchmark the creep resistance of Neoloy Tough-Cells vs. HDPE Soft-Cells.

Failure is defined as >3% total creep due to the loss of confinement of the cell, and subsequent loss of compaction.

Creep in the HPDE based Soft-Cells is severe and reaches failure within 1.9 years in moderate loads and within only 1.5 months after installation in heavier loads. This raises serious questions about the design life of HDPE Soft-Cells and their use in long-term, road reinforcement projects.

As seen below, PRS-Neoloy® Tough-Cells have < 3% elongation over a project design life.

Graph of comparison of HDPE Soft-Cells vs Neoloy Tough-Cells creep deformation vs. design life (base layer load)

The following table summarizes the SIM test results per different Neoloy Tough-Cells Categories

| CREEP RESISTANCE (PERMANENT DEFORMATION) | ||

| PROPERTIES | MINIMUM REQUIREMENT | TEST METHOD |

| Permanent Deformation: | All Categories – B, C, D | |

| 30°C

45°C 60°C |

Accumulated |

ASTM D-6992 (SIM); Loading at:

4.4 kN/m (subbase) – B 6.1 kN/m (base layer) – C, D |

Benefits

The high creep resistance of Neoloy maintains the stiffness and dimensional stability of the PRS Neoloy Tough-Cells over time.

This enables the use of a low reduction factor for the design and reliable confinement for a period of 75 years and more (dependent on project-specific conditions); and makes Neoloy Tough-Cells suitable for all types of long-term reinforcement applications, e.g., highways, ports, railways, container yards, reservoirs, landfills and retaining walls.

HDPE Soft-Cells do not mention the SIM test or any other accelerated test of creep behavior.