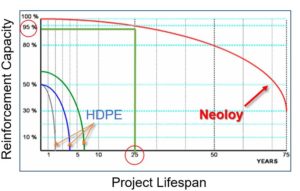

Neoloy® Tough-Cells Maintain Engineering Properties Over Time

Compared to HDPE Soft-Cells, Neoloy Tough-Cells maintain greater stiffness, bearing capacity and stress distribution, while reducing deformation.

Not all geocells are the same. While HPDE Soft-Cells have relatively low tensile strength, high creep and low dimensional stability, Neoloy Tough-Cells have high modulus and tensile strength, making them suitable for long-term applications.

Benefits of PRS Neoloy Tough-Cells over HDPE Soft-Cells

| EASY LOGISTICS / INSTALLATION | USE LOCAL MARGINAL SOIL | LONG-TERM LIFESPAN | HIGH STRENGTH & STIFFNESS | LOW ENVIRON-MENTAL IMPACT | |

| PRS NEOLOY Tough-Cells |

V |

V | V | V | V |

|

HDPE Soft-Cells |

V | V | X | X | X |

- Higher tensile strength – up to 25 kN/m

- Higher flexural storage modulus – 3-10x higher plastic deformation (creep) resistance

- 2 to 5x higher dimensionally stable in a much wider temperature range

- Significantly more resistant to stress-cracking

- Very high resistance to elevated temperatures up to 60°C

- 10x more resistant to oxidation and UV degradation over time

Recent research has broadened our understanding of geocells and the reinforcement mechanisms. The results prove that not all geocells are equal – a key to performance is the elastic modulus of the geocell.

Soft-Cells manufactured from HDPE have relatively low tensile strength, high creep and low dimensional stability.

HDPE Soft-Cells are unsuitable for long-term applications, particularly when subject to heavy-duty cyclical loading and elevated temperatures.

Neoloy Tough-Cells maintain their engineering properties over time, under heavy loading and under high temperatures. This has been confirmed by numerous plate-load tests, numerical modeling and full scale trafficking tests (see Neoloy Published Research). Neoloy Tough-Cells have demonstrated greater improvement in stiffness, bearing capacity, stress distribution and reduced deformation, when compared with conventional HDPE Soft-Cells. The high modulus and tensile strength of Neoloy Tough-Cells make it the most suitable geocell for long-term use in motorways, railways and earth retention.