The Stepped Isothermal Method (SIM) was developed to predict the accelerated creep of polymers for a lifespan of 50-100 years (ASTM D6992). SIM measures the cumulative plastic distortion of the polymer product by subjecting it to a constant load at different temperatures for a specified time. The SIM method enables the calculation of the allowed strength for long-term design.

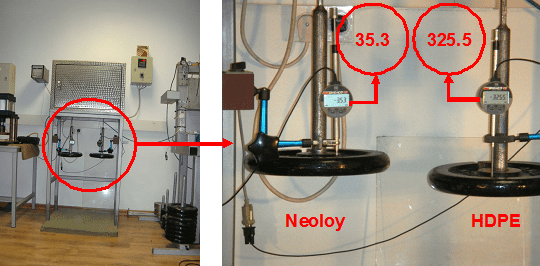

In the SIM test the End of Life is not based on the cell wall or seam rupture, but rather a permanent plastic deformation exceeding 10%. Polyolefin (PE, PP) tends to fail unexpectedly at strains above 10% caused by “crazing” in the polymer chemical structure, leading to a loss of confinement and failure. Accelerated creep of the Neoloy® Tough-Cells sample is ~9x lower than the HDPE sample as shown in the test below.

| MECHANICAL PROPERTIES – TENSILE STRENGTH | |||

|---|---|---|---|

| DESCRIPTION | VALUE | UNITS | TEST METHOD |

| Strength at Yield | 24 | kN/m | ISO 10319 |

| (minimum value) | -1 | ||

| Resistance to Permanent Deformation (Creep) Reduction Factor | < 1.50 | - | ASTM D-6992 (SIM) |

| 5 years | <1.75 | ||

| 10 years | <2.25 | ||

| 25 years | <2.70 | ||

| 50 years | |||

| (1) Standard ISO 10319 test modified to achieve more accurate results by using more representative test sample size; strip is cut adjacent to 2 seams and clamped so distance between clamps is 1/2 of cell height; Test direction is perpendicular to seams. | |||

| Test sample measured at strain rate 20%/min, 23°C; |

This technique “accelerates” the creep by increasing the temperature in steps and then shifts the data (using time-temperature superpositioning principles) to longer time periods. The SIM technique allows for more than 10,000 hours of creep to be simulated in less than 24 hours.