High Elastic Stiffness Guarantees Long-term Performance

Geocell resistance (elastic stiffness) to plastic deformation under different mechanical stresses, frequencies and temperatures provide an accurate validation of geocell performance for long-term design

Polymers tend to lose elastic modulus over time, particularly under dynamic loading. A geocell system must maintain stiffness and elastic properties without permanent deformation or loss of geometry, which could result in losing confinement or even worse crack and fail.

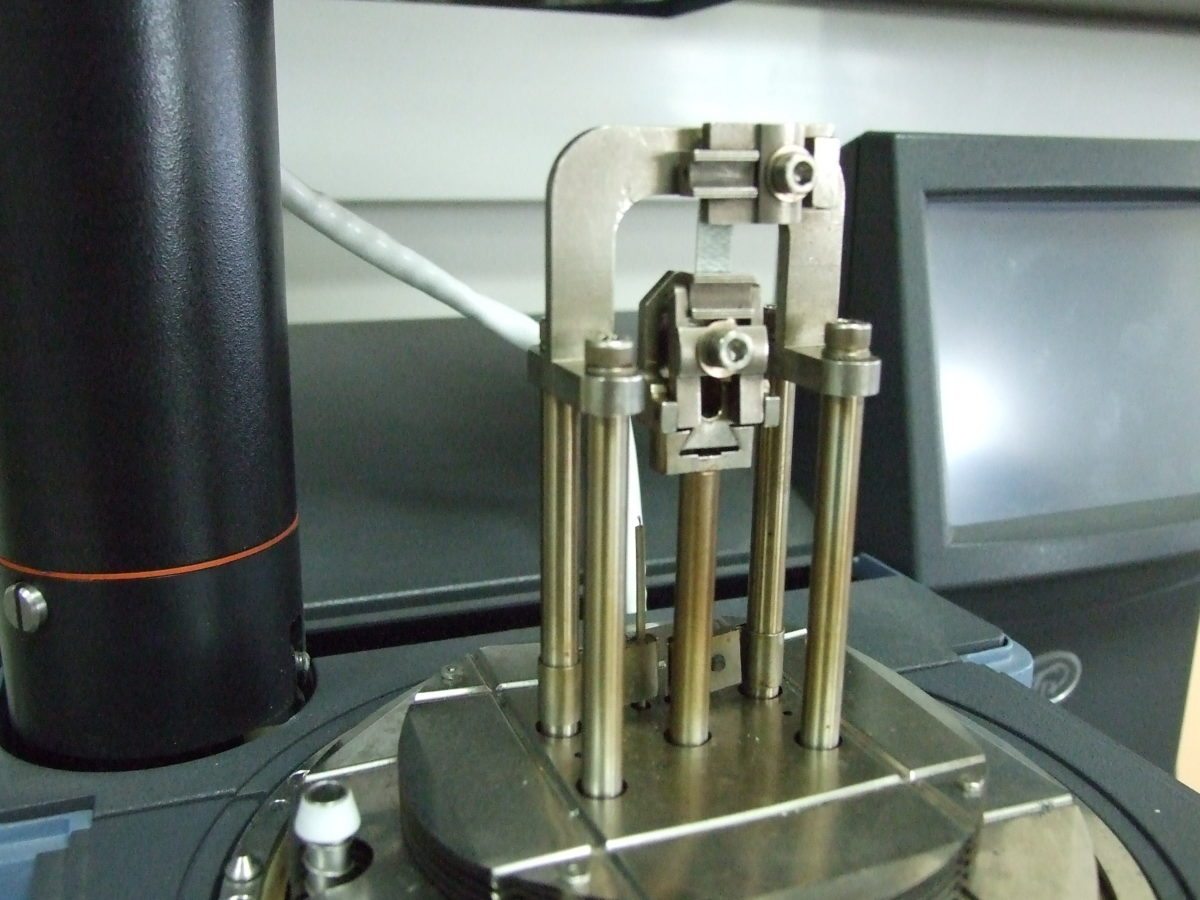

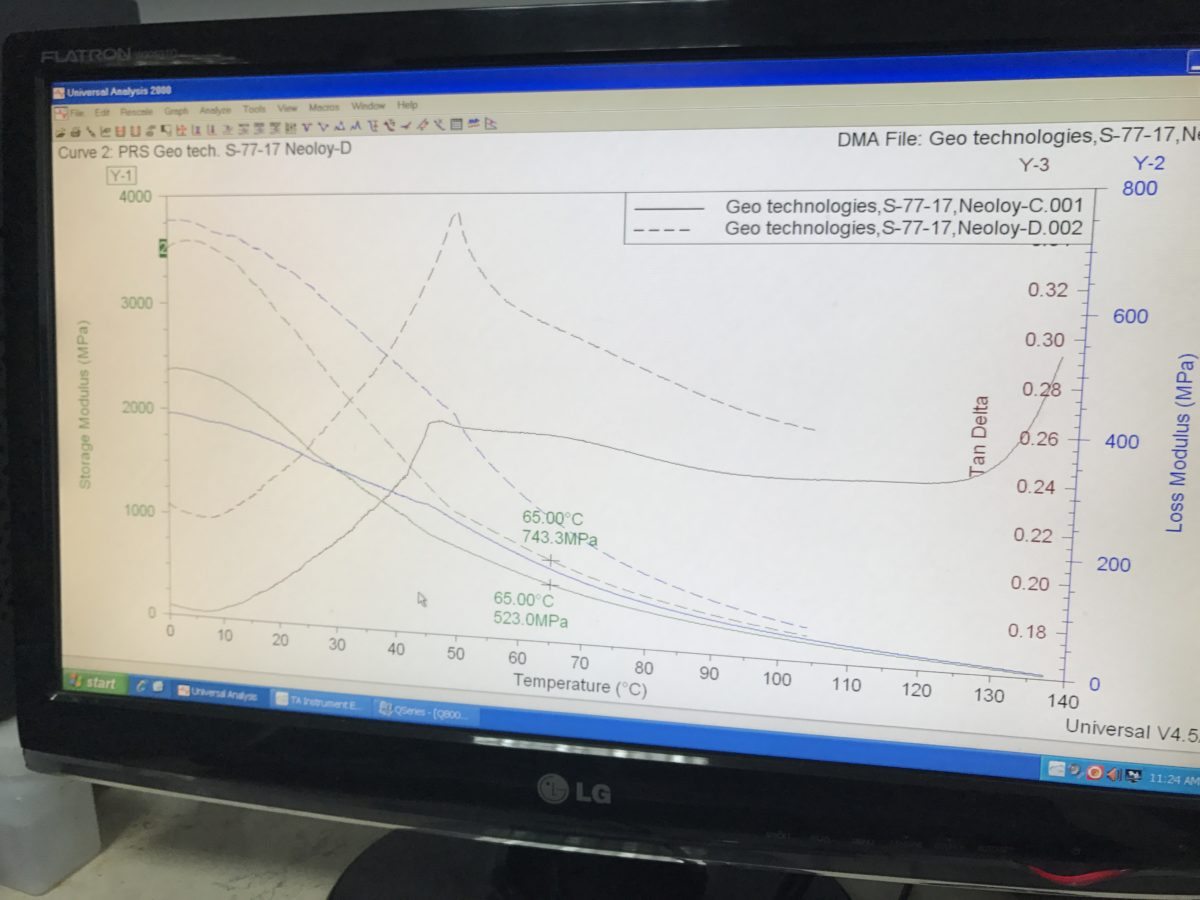

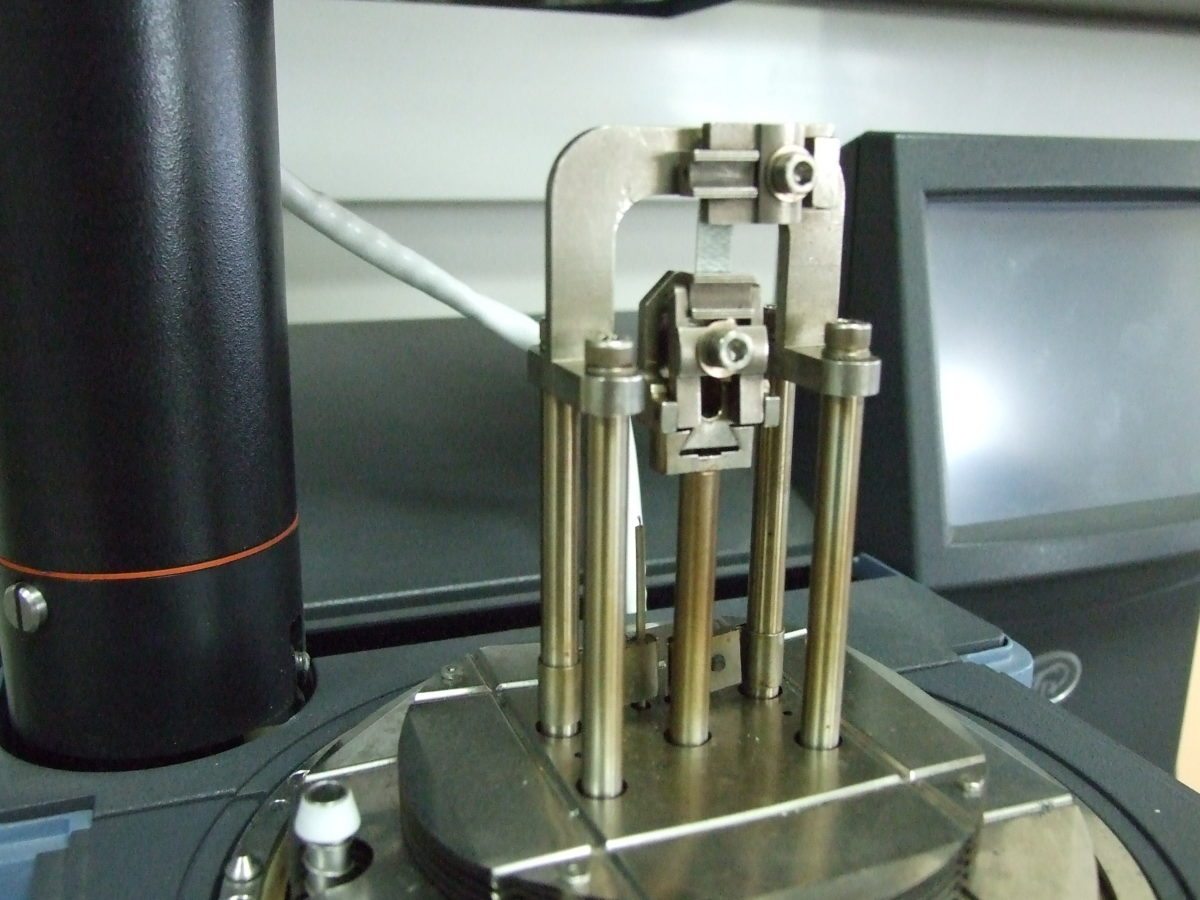

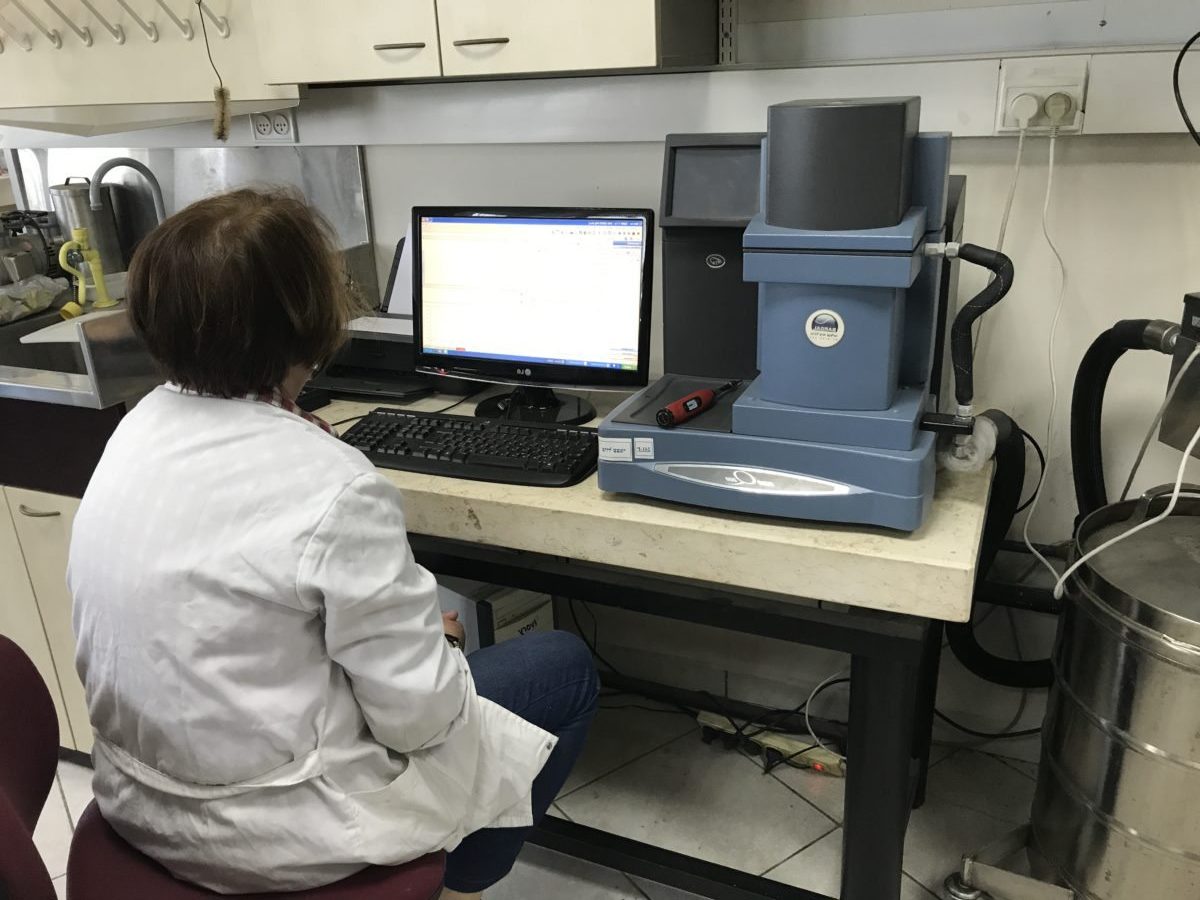

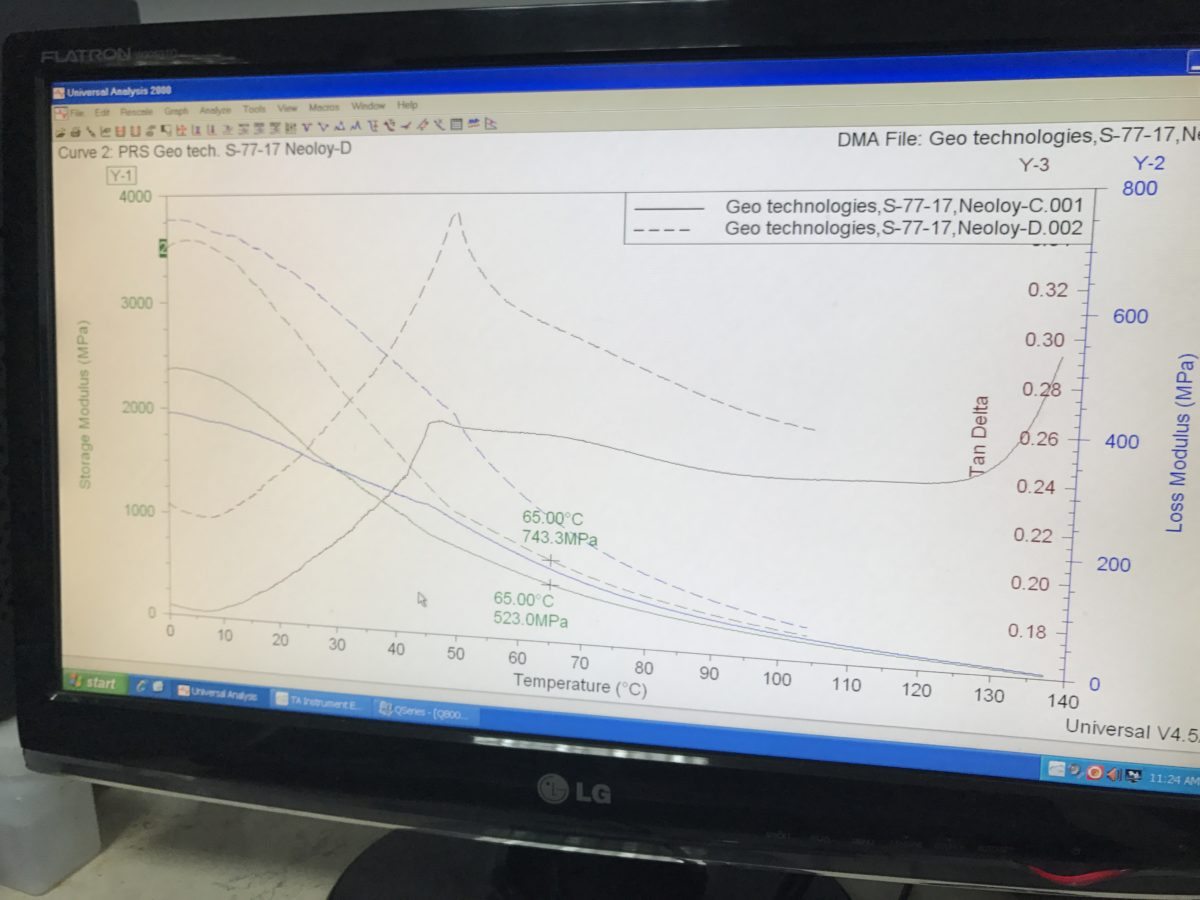

The Dynamical Mechanical Analysis (DMA) examines the net elastic modulus of polymers. The analysis extracts the polymer stiffness in the elastic mode – the ability to apply loads (stress) on the system without permanent deformation. A stable net elastic modulus also ensures elastic behavior at elevated temperatures (flexible storage modulus)..

This method is well supported by ASTM and ISO standards e and commonly used in the automotive, electronic, military industries. The following table summarize the PRS Neoloy® Tough-CellsElastic (Stiffness) Modulus Properties.

| PERFORMANCE AT ELEVATED TEMPERATURES | |||

|---|---|---|---|

| DESCRIPTION | VALUE | UNITS | TEST METHOD |

| Flexural Storage Modulus at sample temp: | |||

| 30°C | > 725-800 | MPa | ISO 6721-1 |

| 45°C | > 650-700 | ASTM E2254 | |

| 60°C | > 475-600 | (DMA) |

Download PRS-Neoloy Tough-Cells specifications to see engineering properties

The DMA also enables the effective service temperature range (elastic behavior) by a mathematical determination: the Neoloy Tough-Cells effective service range is -60°C to +60°C. Higher DMA values mean higher elastic modulus, from the initial project installation to the end of design life.

Unlike HDPE Soft-Cells, Neoloy Tough-Cells show predictable stiffness at typical as well as elevated temperatures for accurate risk analysis and long-term design. HDPE Soft-Cell manufacturers do not reference this property or test.

The DMA analysis is performed in the range plus 150°C to minus 150°C.