Neoloy Geocells – the Smart Innovation in Cellular Confinement Systems

Making Cellular Confinement Systems with Long-term Strength for Today’s Demanding Transportation and Infrastructure

What is a Cellular Confinement System?

A 3D cellular confinement system is a honeycomb geocell structure created by the 3D interaction of soil, cell walls and geometry. Geocell cellular confinement system maintains soil compaction, thereby increasing the structural strength of the infill and pavement layer.

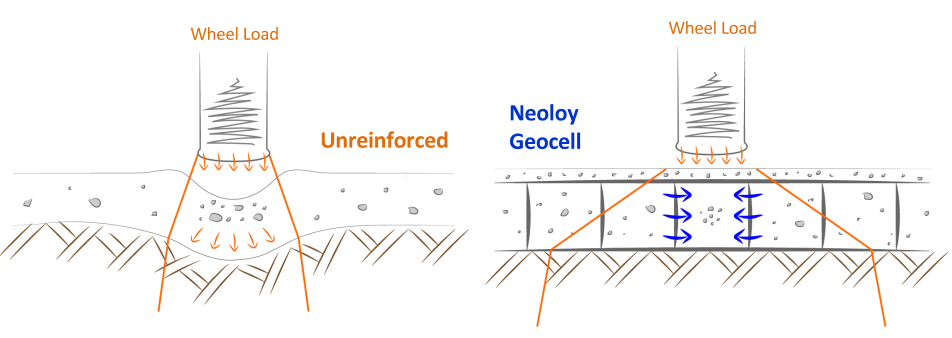

The key geocell reinforcement mechanisms are lateral and vertical cellular confinement, beam effect and improved load distribution. When the confined soil within a geocell is subjected to loading, it causes lateral stresses on the cell walls. The 3D zone of cellular confinement reduces the lateral movement of soil particles while vertical loading on the contained infill results in high lateral stress and resistance on the cell-soil interface.

Load distribution showing the effect of cellular confinement with and without Neoloy Geocell

The high-strength geocell mattress created by Neoloy-based geocells, acts as a flexible beam, which reduces stress and settlement. In addition cellular confinement increases the elastic modulus values of granular infill materials, particularly marginal fill, such as fine granular soils and recycled materials.

These mechanisms highlight the importance of geocell tensile strength, & elastic stiffness and creep resistance critical differences between PRS- Neoloy Geocells and other HDPE based geocells.

Contact us for more info about Neoloy Cellular Confinement Systems

Benefits

- Key Advantages – high elastic stiffness, low creep, high tensile strength

- Improved Load Distribution

- 80% less rutting

- 70% saving in granular infill

- Enable use of marginal soil for infill

- x5 Improvement in Asphalt Layer

- 35% less asphalt

- 35% savings in base/subbase layers

- Enables use of RAP for infill

- Improved Modulus of Adjacent Layers – x7.6 Jump

- transfers vertical forces to hoop stresses and by passive resistance.

- Proven Results – supported by 55 published papers.

- Guaranteed 75 year performance

- Excellent hoop strength and stiffness – prevents deformation and increases durability

- 3D zone of influence – to maximize the reinforcement mechanism

- High creep resistance – enables reliable long-term performance

- Better load transfer – by reducing applied load settlements

- Reduced aggregate attrition – from traffic vibrations

- Subbase spreads applied traffic loads – thereby reducing vertical stresses on subgrade

- Lower vertical stresses – increase subgrade strength and reduce thickness of structural layers

- Lower construction costs – initial savings

- Increase pavement lifespan –lifecycle saving

Neoloy Geocells are used in following applications

- Road Base Reinforcement – see UNOPS South Sudan rural roads project.

- Railway Track Reinforcement – see Amtrak High Speed Track Stabilization on Soft Clay.

- Heavy Loads Platforms Stabilization – see Mexico Airport Engineering Testimonial.

- Slope and channel erosion protection – see Slope Protection, Mexico.

- Earth stabilization and retaining walls – see retaining wall case study in Turkey.

- Landfill & Reservoir geomembrane protection – see pond embankment case study in India.