Courtesy of Paradox Access Solutions, Authorized PRS Distributor in North America

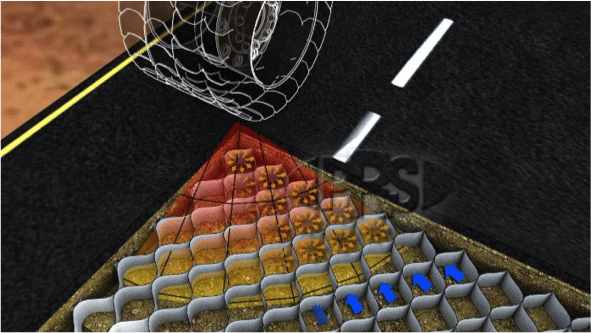

PRS Neoloy Tough-Cells are a green 3D mechanical soil stabilization technology to stabilize all kind of soils, reinforce support layers and deliver the highest pavement performance. Increased performance enables heavy-duty use and extended service life, with the lowest repairs and maintenance compared to unreinforced methods. With engineering properties aligned to transportation and infrastructure needs, Neoloy Tough-Cells present the strongest solution and extended the life of pavements, rails and ports. In addition, Tough-Cells can be used for slope and channel protection, earth retention walls and landfills and reservoirs.

Geocells with granular fill act as a mattress that later distributes applied vertical forces (e.g., vehicle wheel). The confinement restrains the lateral movement of soil particles via hoop stress on the cell walls. The stabilized soil improves layer modulus and reduces surface deformation. However, the extent of the reinforcing or stabilizing effect is determined by the “material from which the product is made …. geocells must also have the right properties … when it comes to dynamic stiffness, resistance to plastic deformation and tensile strength” (Reinforcement Geosynthetics in Road Building Standard(Vega et al, 2018, Netherlands).

PRS guarantees the geocell performance for the entire project design life

Although the geometry of geocells is similar, it is the polymeric material from which they are made that determines their performance. There are 2 main types:

Neoloy® Tough-Cells are rigid geocells made from NPA (Novel Polymeric Alloy), providing the stiffness, strength, and durability required to resist volumetric deformation under dynamic loading throughout the project lifespan – delivering the highest value and the most effective soil stabilization solution. According to global standards, such as ASTM and ISO standards, the three key properties of cells are:

Whereas one size doesn’t fit all, one cell type does not fit all projects. Neoloy Tough-Cells are manufactured in 4 strength categories (C-D) to match the geocell to the specific project requirements. This enables you to customize the geocell configuration to the project and optimize the solution performance vs. cost. Learn how to use Neoloy Tough-Cells Categories to optimize your performance and costs.

PRS Neoloy Tough-Cells are geocells suited to the needs of today’s infrastructure and construction by providing the highest engineering performance at the most effective cost. PRS Neoloy Tough-Cells provide the strongest stabilization, highest reinforcement factors and/or lowest costs (capital and lifecycle) compared to any unreinforced or geosynthetics alternative:

Polymers tend to lose elastic modulus over time, particularly under dynamic loading. A geocell system must maintain stiffness and elastic properties without permanent deformation or loss of geometry, which could result in losing confinement or even worse crack and fail.

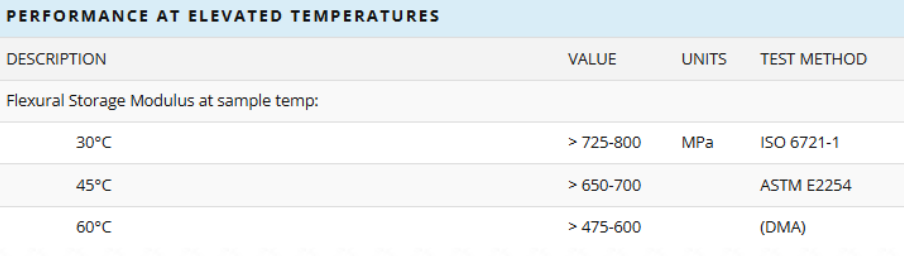

The Dynamical Mechanical Analysis (DMA) examines the net elastic modulus of polymers. The analysis extracts the polymer stiffness in the elastic mode – the ability to apply loads (stress) on the system without permanent deformation. A stable net elastic modulus also ensures elastic behavior at elevated temperatures (flexible storage modulus)..

This method is well supported by ASTM and ISO standards e and commonly used in the automotive, electronic, military industries. The following table summarize the PRS Neoloy® Tough-CellsElastic (Stiffness) Modulus Properties.

The DMA also enables the effective service temperature range (elastic behavior) by a mathematical determination: the Neoloy Tough-Cells effective service range is -60°C to +60°C. Higher DMA values mean higher elastic modulus, from the initial project installation to the end of design life.

Unlike HDPE Soft-Cells, Neoloy Tough-Cells show predictable stiffness at typical as well as elevated temperatures for accurate risk analysis and long-term design. HDPE Soft-Cell manufacturers do not reference this property or test.

The DMA analysis is performed in the range plus 150°C to minus 150°C.

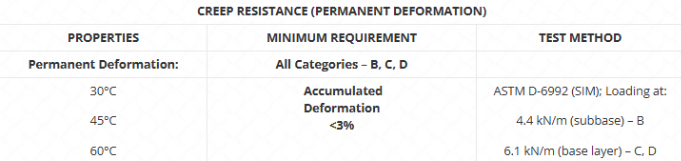

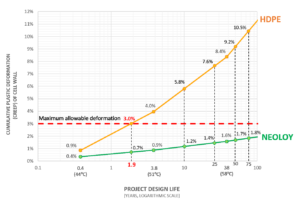

The Stepped Isothermal Method (SIM) test is used to predict the creep (elongation) of polymers for the project design life (ASTM D6992). SIM measures the cumulative plastic distortion of the polymer product by subjecting it to a constant load at different temperatures for a specified time. The SIM method enables calculation of the allowed strength for long-term design.

The video above demonstrates a SIM test of Neoloy Tough-Cells vs. HDPE Soft-Cells. The weights represent a heavy-duty load (6.1 kN/m). The temperature is raised in 4 steps to simulate acceleration of time to a design life of 75 years.

The end of service life in the SIM test is not based on a geocell wall or seam rupture, but rather on a permanent plastic deformation exceeding 3%. Plastic deformation above 3% causes expansion in the cell walls such that the cell loses its compaction; leading to a loss of confinement and potential failure.

Geocells with granular fill act as a mattress that later distributes applied vertical forces (e.g., vehicle wheel). The confinement restrains the lateral movement of soil particles via hoop stress on the cell walls. The stabilized soil improves layer modulus and reduces surface deformation. However, the extent of the reinforcing or stabilizing effect is determined by the “material from which the product is made …. geocells must also have the right properties … when it comes to dynamic stiffness, resistance to plastic deformation and tensile strength” (Reinforcement Geosynthetics in Road Building Standard(Vega et al, 2018, Netherlands).

While developing a Neoloy®-based geocell unlike any other, PRS also set a new range of standards to measure the its performance, as the general industry standards are outdated.

Together with experts in geosynthetics (TRI, GRI, ASTM), PRS adopted new test methods for geocells, based on widely-accepted testing methods for polymer plastics in other industries. In addition to conventional seam weld and tensile strength properties, the advanced test methods utilized by PRS predict long-term behavior and accumulated plastic strain in a geosynthetic under loading with different mechanical stresses, frequencies and temperatures. These methods include:

These test methods more accurately reflect 3D geocell geometry and material performance in the field rather than tests of individual strips and virgin materials. Although not yet adopted by the geocell industry these commonly used ASTM/ISO standards have been adopted by PRS for reliable and verifiable assessment of geocell properties and long-term performance.

Conclusion: Neoloy Tough-Cells – The only qualified geocells for long-term

The test results summarized in the graph below show the relationship between (tension) creep and project design life and infill settlement. The graphs benchmark the creep resistance of Neoloy Tough-Cells vs. HDPE Soft-Cells.

Failure is defined as >3% total creep due to the loss of confinement of the cell, and subsequent loss of compaction.

Creep in the HPDE based Soft-Cells is severe and reaches failure within 1.9 years in moderate loads and within only 1.5 months after installation in heavier loads. This raises serious questions about the design life of HDPE Soft-Cells and their use in long-term, road reinforcement projects.

As seen below, PRS-Neoloy® Tough-Cells have < 3% elongation over a project design life.

The following table summarizes the SIM test results per different Neoloy Tough-Cells Categories

The high creep resistance of Neoloy maintains the stiffness and dimensional stability of the PRS Neoloy Tough-Cells over time.

This enables the use of a low reduction factor for the design and reliable confinement for a period of 75 years and more (dependent on project-specific conditions); and makes Neoloy Tough-Cells suitable for all types of long-term reinforcement applications, e.g., highways, ports, railways, container yards, reservoirs, landfills and retaining walls.

HDPE Soft-Cells do not mention the SIM test or any other accelerated test of creep behavior.

Geocell integrity is dependent on the strength of the perforated strip and the weld (~90 degrees).

A tensile testing machine is used to determine the geocell tensile strength and seam weld strength. The strength of the weld on the strip must be equivalent or higher to the tensile strength of the strip itself.

While developing a Neoloy®-based geocell unlike any other, PRS also set a new range of standards to measure the its performance, as the general industry standards are outdated.

Together with experts in geosynthetics (TRI, GRI, ASTM), PRS adopted new test methods for geocells, based on widely-accepted testing methods for polymer plastics in other industries. In addition to conventional seam weld and tensile strength properties, the advanced test methods utilized by PRS predict long-term behavior and accumulated plastic strain in a geosynthetic under loading with different mechanical stresses, frequencies and temperatures. These methods include:

These test methods more accurately reflect 3D geocell geometry and material performance in the field rather than tests of individual strips and virgin materials. Although not yet adopted by the geocell industry these commonly used ASTM/ISO standards have been adopted by PRS for reliable and verifiable assessment of geocell properties and long-term performance.

The procedure utilizes a “wide-width” sample size, such that it includes a representative distribution of the strip wall perforations from seam to seam. (A ½ cell length can be used if the perforation pattern on each side is identical.)

A longitudinal force is applied to the test specimen at a constant strain rate at 100 mm/minute for load support applications – until the specimen ruptures. Measurement is performed by extensometer; tensile strength, strain at maximum load (in %) and stiffness are recorded and normalized for the thickness.

The test is carried out until the yield point, which indicates the geocell material strength

A longitudinal force is applied at 100 mm/minute until the specimen ruptures

PRS Tough-Cells offer the highest tensile strength compared to any other geocells and PRS is the only manufacturer to guarantee minimal tensile strength for perforated and non-perforated strips.

The following are the minimum geocell tensile strength values for categories B-D (±7%) according to ISO 10319:2015:

Testing geocell seam weld strength is useful for quality control purposes. However, it is not a factor in engineering design, as the geocell strip will fail before ultrasonically welded seams, due to the perforations that weaken it.

A test of the geocell seam weld strength should reflect the 3D geometry of a geocell and its composite behavior as a mattress system in the field, not as an individual cell. Part 1 of the existing ISO standard lists four different geometries (A-D) for conducting the “weld strength” test. Method C – the SPLIT test – best simulates the geocell geometry at ~90° similar to an installed geocell in the field.

To simulate the 90° forces, an X-shaped sample from the geocell is wrapped round two rollers in a jig apparatus clamped to the tensile test machine. The test is conducted at a rate of 100 mm/min, until a tensile split failure of the weld occurs.

X-shaped sample is wrapped in a jig apparatus clamped to the tensile test machine

The following are the minimum geocell seam weld strength values for categories B-D (±7%) according to ISO-13426-1,

Part 1, Method C:

Stabilizers that prevent polymer degradation from UV radiation belong to the Hindered Amine Light Stabilizers (HALS) family of heat stabilizers; these are essential additives that allow PRS-Neoloy® Tough-Cells to survive exposure to heat and direct and diffused solar radiation as well as to free radicals (oxidative processes in the environment) for tens of years.

The heat stabilizer content is measured by the High Pressure – Oxidative Induction Time (HPOIT) method (ASTM D5885). HPOIT is an accurate indicator of the long-term reliability of the polymer protection to withstand prolonged exposure to oxidation. This method is widely used for testing the environmental durability/UV resistance of geosynthetics in critical applications.

GEOCELL ENVIRONMENTAL DURABILITY | |||

PROPERTIES | MINIMUM REQUIREMENT FOR ALL CATEGORIES | UNITS | TEST METHOD |

Durability to UV Degradation | >1600 | minutes | ASTM D5885 |

The results show that PRS-Neoloy Tough-Cells are durable under the following environmental conditions: