Neoloy Tough Cells 3D mechanical stabilization technology maintains track geometry and reduces maintenance by 6.7x

Railway track geometry and maintenance is very sensitive to the track substructure, subgrade and/or ballast conditions and train speeds and loads. In fact, the cost of maintaining such infrastructure over time (Total Cost of Ownership) determines the economic worthiness and success of track engineering solutions and not the initial railway construction or rehabilitation cost.

Neoloy Geocells, at the ballast/subgrade interface area have been shown to decrease the rate of track surface geometry degradation (both surface and cross-level) under a range of traffic loadings.

The ability of Neoloy railway track reinforcement solutions to reduce the rate of degradation, particularly in these high degradation rate locations, is of great value for both in the construction of new railway lines and in the maintenance of existing lines.

The railway construction benefits are better track quality, higher train speeds and loads, less downtime, lower maintenance costs, and more profitable operations.

The Neoloy material enables a high modulus, creep resistant and strong geocell, based on the following performance properties, which are validated by ISO and ASTM standard testing procedures:

Neoloy Geocells offer cost-effective ground reinforcement solution for substructure layers, embankments, turnouts and train yards, as well for earth stabilization solutions for slope protection, railway abutments and earth berms and noise barriers.

Stabilization of embankments on soft subgrade in railway construction with Neoloy Tough-Cells is simple to build and more cost effective than alternatives.

The construction of embankments for railways over poor subgrade is a frequent problem. Stability is a concern for safety and to prevent settlement of the railway track superstructure. Railway embankment construction often uses deep foundations such as vibro stone columns, piles and soil replacement, but these solutions are expensive. Railway professionals need more economical solutions.

Geocells are a proven soil reinforcement method that is strong and cost-effective soil and simple to construct. railway embankments. The strongest, stiffest and most creep resistant geocell is the Neoloy Tough-Cells from PRS – the geocell of choice amongst railroad engineers. Railway embankment stabilization with Neoloy Geocells increases soil bearing capacity strength by 4-6x. Extensive research and field results showed that Neoloy Geocell reinforcement increased stiffness of railway embankments by 164% and prevented deformation of both the foundation and surface.

Experimental, analytical and project case studies of railway and other embankments have demonstrated that Neoloy Geocells reduced vertical deformation and lateral displacement as follows:

The researchers concluded that “The confinement mechanism of reinforcement was very effective making the railway ballast/Neoloy composite very stiff, strong and durable…. Neoloy Geocells could be an excellent tool in roadway subgrades, railroad ballasts, and embankment construction”.

Neoloy Tough-Cells give engineers a single soil stabilization strategy for an entire railway infrastructure project and more.

Neoloy Tough-Cells give engineers a single soil railway track stabilization strategy for an entire railway infrastructure project. In addition to load support, Neoloy provides integrated railway track stabilization and slope/channel protection for the embankments, retaining walls, flyovers, and stream diversions typical of the railway development projects.

Unconfined ballast spreading laterally and causing settlement is a main reason for track maintenance.

Unconfined ballast spreading laterally and causing settlement is a main reason for track maintenance. Attrition from the relative movement of ballast particles under high cyclical loading from rolling stock is the major cause of ballast degradation, along with ballast abrasion and breakage. The result is frequent tamping cycles.

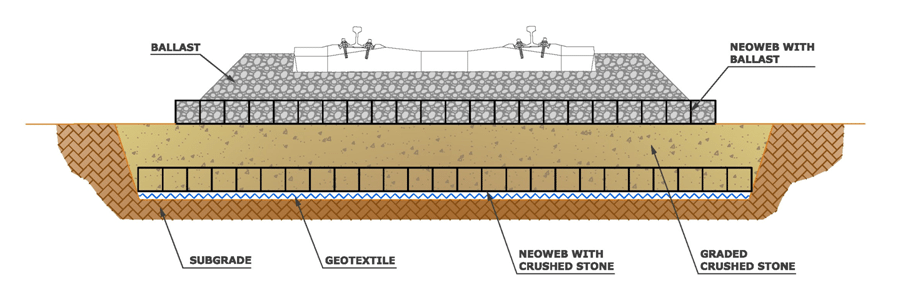

Neoloy cellular confinement installed at the ballast/subgrade interface can reduce surface geometry degradation. The stiff confinement provided by Neoloy Geocells minimizes the relative movement of particles, prevents aggregate abrasion and attrition, and reduces lateral and vertical deformation in the track support structure. Ballast confinement increases its stiffness while restraining lateral movement. This prevents shearing of aggregate under loading. The ballast (and cell walls) is additionally strengthened by the cell wall hoop stresses and by passive resistance from surrounding cells.

Neoloy Tough-Cells reinforce the track substructure layer underneath the ballast layer. It reduces degradation of the embankments by creating a stiff mattress.

The long-term performance of the substructure under the ballast layer is critical as it is not subject to regular maintenance. Neoloy Geocells reinforce the track substructure layer underneath the ballast layer. It reduces degradation of the rail embankments by creating a stiff mattress (semi-rigid platform), which behaves more like a three-dimensional semi-rigid slab or beam effect. The high shear strength and greater load distribution of Neoloy Geocells reduce vertical stresses reaching the subgrade.

The increased bearing capacity of the subgrade strengthens the subballast layer and reduces settlement and accumulated degradation, thereby preventing deformation of the rail embankments. Neoloy reinforcement of the track substructure over problematic subgrade reduces surfacing cycles on the order of double or even more, and enables faster train speeds and heavier loads.

In addition lower quality infill can be utilized in place of expensive well-graded subballast aggregate, while the thickness of the subballast layer can be reduced by up to 50% with no reduction in structural strength.