Neoloy® Tough-Cells enable sustainable, cost-effective, reliable, and long-term solutions for unpaved roads outperforming any unreinforced solution such as geogrids, HDPE geocells, or other ground methods.

Although 80% of the world’s roads are unpaved, millions of people rely upon them for access, services and resources. However, these roads often face multiple challenges – soft soils, insufficient aggregate, maintenance and drainage, as well as accelerated rutting and degradation. That’s where you need a strong, reliable and reinforced solution – Neoloy.

Neoloy Tough-Cells provides a sustainable reinforcement solution for a wide range of applications, including unpaved roads. They stabilize all types of subgrades and reinforce the unbound base layer of access roads, haul roads, gravel roads, and rural, low-volume, or temporary roads.

Neoloy Tough-Cells, made from a high-strength Novel Polymeric Alloy (NPA), enable the following performance benefits:

Engineering companies and consultants worldwide collaborate hand-to-hand with PRS Engineering Department to integrate the proven Neoloy Technology into ground stabilization and pavement projects.

At the core of Neoloy’s performance lies its unique Novel Polymeric Alloy (NPA), delivering high stiffness (>500 MPa @ 60°C) and exceptional durability. This rigidity creates a semi-rigid slab effect, increasing layer modulus by up to 500%, as verified in Accelerated Pavement Testing (APT).

Neoloy Tough-Cells enable the use of locally available, recycled, or marginal-quality materials for infill, while maintaining structural integrity. This makes it possible to design roads with up to 75% thinner layers, achieving substantial savings in materials, construction time, and environmental impact

PRS Neoloy solutions are based on the official design methodologies, unique Neoloy Improvement Factors, International Standards, 120+ Academic Publications, and thousands of monitored projects. All resulted in the most valuable, effective and comprehensive solutions, ensuring a tailored fit for each project’s unique challenges.

The Neoloy Technology guarantees cost savings, time efficiency, enhanced performance, and long-term sustainability, providing a solution that is both technically superior and economically viable.

Neoloy enables quick and easy installation across various applications, adapting effortlessly to different soil types and conditions – all-weather construction in extreme climates/conditions – With a robust global network, PRS provides comprehensive end-to-end support services, ensuring tailored and industry leading solutions that meet each project’s unique needs.

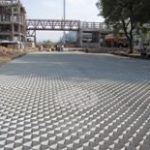

Access Road, Clay Soil, India (Read More)

Haul Road, Sand Infill, Canada (Read More)

Logging Road, Soft Soil, Uruguay (Read More)

Stabilize your Road to Access Crude Oil & Natural Gas

Oil & Gas companies use Neoloy® Tough-Cell solutions to find, produce and deliver energy with access roads that can handle any load, over any soil.

Exploration for upstream crude oil and natural gas often takes place in the most challenging environs – deserts, arctic tundra, mountains and jungles. Getting heavy drilling equipment in and erecting rigs and pipelines to get it out requires roads. And extensive soil stabilization efforts.

Neoloy Tough-Cells provide a strong and cost-effective solution access for energy exploration anywhere. Implemented by energy producers worldwide, Neoloy Tough-Cells are easy to transport and deploy in remote locations. The 3D mechanical confinement strengthens marginal quality granular materials for infill. This not only eliminates the need to import aggregate to remote areas. It also creates stiff, strong and durable access roads. This is a key success factor for the long-stretches of roads and pipelines needed for energy production.

Strength and durability are also key factors to choosing a geocell. The unique Neoloy novel polymeric alloy (NPA) provides the highest stiffness and creep resistance of any geocell. This ensures reliable access of even the heaviest of rigs and equipment. –With an effective service range from -60° to +60°C, Neoloy Tough-Cells enable reliable all-weather construction and use for year-round exploration, service and extraction.

In projects for the Gazprom energy company in the harsh climate of Siberia, Neoloy Tough-Cells provided effective all-weather road reinforcement. Neoloy Tough-Cells were at the foundation for reliable access and service roads for pipeline routes season after season, well beyond customer expectations. (Read more)

Neoloy® Tough-Cell haul road reinforcement keeps the heavy haul trucks moving over all kinds of soils in all-weather conditions.

Haul roads and haul trucks are the lifeline of mining and natural resource extraction industries. That’s why Neoloy Tough-Cell designed for heavy duty pavements can keep your mining haul trucks rolling with soil stabilization and reinforced haul road bases – even in rainy seasons and freeze-thaw cycles.

Neoloy Tough-Cells meet these challenges by stiffening haul road pavements using marginal infill material. Keep the haul trucks rolling by stabilizing soft subgrade soils and reinforcing roads with rigid Neoloy geocells for all-weather use. Neoloy Tough-Cell reinforced haul roads resist cuts, impacts and degradation. The result is less wear and tear to tires and vehicles and making them the safest and most economical solution with the lowest operations.

The unique, validated properties of the Neoloy Tough-Cell reinforcement factors provide high dynamic stiffness, resistance to permanent degradation and tensile strength. These properties enable Neoloy Tough-Cells to improve the structural and functional behavior of infill materials, offering the following benefits:

These benefits contribute to a lower environmental footprint: less aggregate and hauling, decreased in-situ earthworks and faster construction. Fuel use, fugitive dust and the carbon footprint are all reduced as are construction time and costs.

Neoloy Tough-Cells is a 3D honeycomb mattress made from Neoloy®. Unlike soft geocells made of HDPE, Neoloy Tough-Cells are a rigid geocell made from Novel Polymer Alloys (NPA) and designed for durable road solutions – suitable for the mining, logging and energy industries. The high elastic stiffness and creep-resistant properties of the NPA material (exceed international standards for rigid geocells) guarantee reliable haul road soil stabilization for heavy-duty loading. Neoloy’s mechanical confinement locks aggregate and binds soil particles This prevents lateral soil movement resulting from vertical loading and increases shear resistance and stiffness (Read more about Neoloy technology here). Neoloy Tough-Cell reinforced haul roads resist cuts, impacts and degradation. The result is less wear and tear to tires and vehicles and making them the safest and most economical solution with the lowest operations.

Stabilize Forest and Logging Roads with Strong, Sustainable and Smart Solution

Neoloy® Tough-Cells create all-weather, sustainable logging roads and log yards on any type of terrain, to increase handling, safety and productivity.

Forests are typically located in regions with mountainous terrain and soft, wet, silty soils. Forest roads require quality design, construction and maintenance, so that foresters can focus their efforts on land management and harvesting timber and not on road repairs and maintenance.

Haul roads and haul trucks are the lifeline of mining and natural resource extraction industries. That’s why Neoloy Tough-Cell designed for heavy duty pavements can keep your mining haul trucks rolling with soil stabilization and reinforced haul road bases – even in rainy seasons and freeze-thaw cycles.

The Neoloy cellular confinement system used for forest road stabilization meets these challenges – with all-weather installation and all-weather road use in soft and saturated soils. The Neoloy Tough-Cell solution creates sustainable forest service roads and logging roads, with a small environmental imprint, using locally available soils for construction.

Logistics is simple as the tough cells arrive onsite in folded sections. These are easily laid out, filled with locally won granular soil, and compacted for immediate use, even by heavy tracked skidders. Subgrade excavation can be reduced or eliminated, while foresters won’t have to sacrifice part of the tree harvest to build log (corduroy) roads, or haul in engineered aggregate.

Neoloy Tough-Cell are designed in a way that they are the stiffness, strongest and with the highest resistance solution compared to all kind of solutions, making them the best management practice for forest roads and logging roads. Neoloy-based Tough-Cell reinforced roads maintain the gravel road surface courses and resist rutting under a load of heavy logging vehicles. This also helps to prevent sedimentation from forest roads in watershed-sensitive areas.

Forest service roads in nature reserves and national parks can be constructed where the minimization of both the environmental footprint and maintenance is critical. Logging roads for timber production are strong, durable and all-weather to improve harvesting production with minimal environmental impact. The fact that forest road structural thickness can be halved while using locally available soil for infill also cuts construction time as well as costs.

When you need maximum strength and protection for ground forces with minimum logistics and road construction you need Neoloy Tough Cells

When you need maximum strength and protection for ground forces with minimum logistics and road construction you need Neoloy is the best available ground improvement solution to construct military roads. It reduces the logistic burden of military road building by using locally available soil – even sand – to reinforce the road base and reduce the road layer thickness. Sustainable and secure routes are also important for civilian reconstruction.

In addition Neoloy Tough Cells can impede tampering of the road surface by hostile forces, thwarting IEDs (improvised explosive device) and protecting lives! Safe patrol routes enable troops to establish control and security.

As proof of Neoloy’s value to armed forces, PRS was chosen by the UK Ministry of Defence (MOD) as its preferred supplier of geocells to construct cost-efficient, reliable roads in challenging environments. Neoloy Geocell performance in combat was demonstrated in Afghanistan in the Trident Route constructed by British Army Engineers. Built under fire and utilizing locally-won sandy soil for infill, the road exceeded all expectations by providing a secure route for patrols while helping to rebuild infrastructure for the civilian population.

In addition to ground improvement for roads for armored vehicles, Neoloy retention walls with earth infill can be used as a fortified wall and barrier system for troops, military road encampments and senstive miitary or civilian facilities.

Do MORE with LESS – Neoloy Tough-Cells are an ideal sustainable road construction technique, offering the highest engineering value at the lowest environmental and economic costs.

Sustainable road construction is a practice that prioritizes minimizing the environmental impact of road infrastructure while ensuring its durability and functionality. It involves using environmentally friendly materials, reducing energy consumption, and preserving natural resources. Neoloy Tough-Cell geocells are a sustainable solution.

Neoloy is a unique sustainable and proven pavement solution for durable road infrastructure that minimizes environmental impacts, recycles materials and takes total lifetime costs into account:

Neoloy Tough-Cells reduce the amount of aggregate in road construction by improving the stiffness and strength of local but marginal soils and recycled materials. This lowers environmental impacts and the carbon footprint significantly. The results are greener construction, with very long-term durability (and reduced maintenance) for any road, rail or port infrastructure project. At the same time, Neoloy also improves pavement performance, lifespan and cost-effectiveness all at the same time.

Neoloy Tough-Cells 3D mechanical confinement system improves the modulus of marginal infill materials Locally available, but poorly graded or partially cohesive marginal soils (e.g., sand) can be used for structural and support layers, as can recycled materials, such as RAP (reclaimed asphalt pavement) and RCA (recycled concrete aggregate). The validated Neoloy reinforcement factor (2.5-5x) also reduces pavement thickness up to 70%, thereby reducing the total amount of infill materials required. These two factors reduce quarrying, hauling, earthworks and soil replacement significantly to create sustainable infrastructure.

Neoloy Tough-Cell sustainability is substantiated in several published studies, which use quantifiable sustainability indicators to compare Neoloy with conventional road construction methods for access road projects. The Neoloy reinforced roads demonstrated: